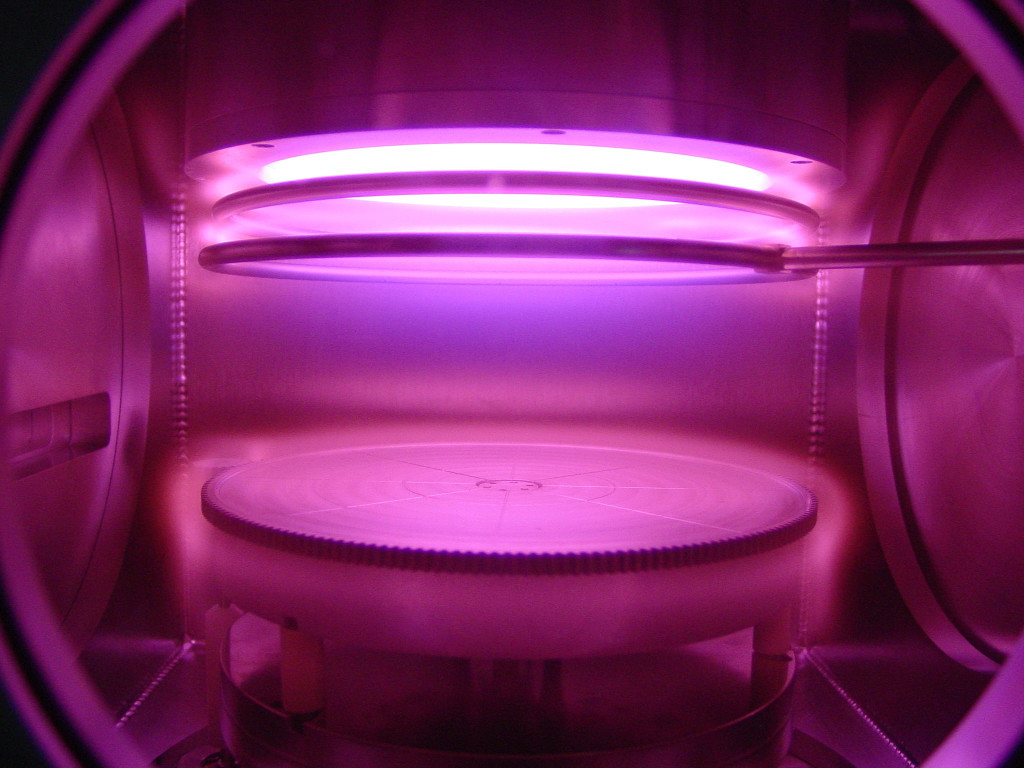

PECVD continues to provide a unique method for electronic deposition.

The process of plasma-enhanced chemical vapor deposition incorporates the use of various materials that are deposited on substrates at lower temperatures than that of your standard chemical vapor deposition method. It’s a trusted technique that continues to be utilized in today’s proprietary processes. This article will break down the basic uses and applications of PECVD.

The process of plasma-enhanced chemical vapor deposition incorporates the use of various materials that are deposited on substrates at lower temperatures than that of your standard chemical vapor deposition method. It’s a trusted technique that continues to be utilized in today’s proprietary processes. This article will break down the basic uses and applications of PECVD.

Process

In PECVD processes, complete deposition is achieved through the introduction of reactant gases between parallel electrodes. These electrodes include both grounded and RF-energized electrodes. The coupling between the electrodes tend to excite the reactant gases to form into a plasma. This will then induce a chemical reaction that will result in the reaction product being deposited onto the substrate. Now, the substrate – which is typically put on the grounded electrode – is heated anywhere between 250 to 350 degrees Celsius – depending on the requirements of the film, Furthermore, CVD also requires 600 to 800 degrees Celsius. The low temperatures of PECVD are vital in numerous applications where CVD temperatures can actually cause harm to the devices that are being fabricated – similar in style to ion beam etching.

Applications

The films that are usually deposited using PECVD are silicon nitride, silicon oxy-nitride, silicon dioxide, silicon carbide, and more. The common materials – silicon dioxide and silicon nitride – are insulating materials that are commonly used in the production of electronic devices because of their multiple conductive layers and surface passivation. These films are also utilized for their encapsulation purposes, which can protect the devices from corrosion from the air – like oxygen, moisture, and varying temperatures.